it can be found at cheaper than dirt if you dont want to wait on shipping

I also use break free CLP on the barrel and all the other little stuff. But the ultma-lube goes in my frame rails.

Moderator: carlson1

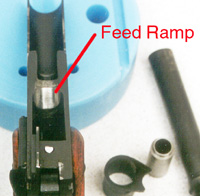

Bunkins wrote: It's internalI did some searching about Kimbers jamming, and really all I could find were issues about external extractor's ( A TON of them ) and failure to extract. I read a little about failure to feed, and from what I could find it seemed most guys polished the feed ramp. A buddy has a full size 1911 Kimber and he polished the feed ramp.. I see a few things wrong with that in my case, I dont know how that would effect the alloy frame. Things such as if it's hardened, if so taking surface material off, you will basicly end up with soft alum. I dont know if the frame is hardened or not, I haven't made it that far yet.. Another issue is corrosion.. Lastly, it's not jamming on the ramp, it's jamming as the round is going into the chamber. From what I'm seeing, and that doesn't mean a lot since I am very new to semi-auto handgun's, is that once the slide becomes rough, it's action is slowing down, therefore causing the round to jam..

NcongruNt wrote:Bunkins wrote: It's internalI did some searching about Kimbers jamming, and really all I could find were issues about external extractor's ( A TON of them ) and failure to extract. I read a little about failure to feed, and from what I could find it seemed most guys polished the feed ramp. A buddy has a full size 1911 Kimber and he polished the feed ramp.. I see a few things wrong with that in my case, I dont know how that would effect the alloy frame. Things such as if it's hardened, if so taking surface material off, you will basicly end up with soft alum. I dont know if the frame is hardened or not, I haven't made it that far yet.. Another issue is corrosion.. Lastly, it's not jamming on the ramp, it's jamming as the round is going into the chamber. From what I'm seeing, and that doesn't mean a lot since I am very new to semi-auto handgun's, is that once the slide becomes rough, it's action is slowing down, therefore causing the round to jam..

The feed ramp is part of the barrel assembly, not the frame.

Bunkins wrote:KillerFly is correct, the feed ramp on mine is in the frame, not the barrel. I'm no handgun expert by any means, but not all 1911's are the same as far as the feed ramps. The SpringField Ultra Compact of my dad's, the feed ramp is built into the barrel. A buddies Kimber ( I want to say TCP, but I'm sure I'm wrong, it's a stainless full size 1911 ), the feed ramp is in the frame..

I put 75 rounds through mine today at the range, and it did great.. But 2 times it failed to pick up the last round in the clip. It may have been my fault, as I was working on grouping my shots with quick follow up's ( shooting as accurately and swiftly as I could ), my thumb may have hit the slide lock. The few times I shot the gun it felt good to me, but today I found that I need to do a bit of customizing. Shooting slowly it felt great, but fast shots it felt as if I was losing my grip. The rear of the gun is loose in my hand, lots of movement. So it's going to need a different set of grips, and probably a extended main spring housing. Thats probably the reason the slide locked on the last round in the clip, the rear of the gun being able to move during recoil, it probably moved enough that my thumb did infact hit the slide lock. I have big hands, so I'm sure thats what it was. The sights were horrible in a indoor range, I couldnt see much of anything. Night sights are very high on the list right now, if I cant aim correctly in low light condition's, the gun is basicly worthless for what I intend to use it for. Still managed a 3 inch group at 15 yards, with only 3 stray bullets in the 75 shots I made. Not my best, I wasn't just real happy with my performance, but I know it will improve once I make some changes to the gun.

My dad's Ultra Compact, I put 30 rounds through it, and it did fail to feed once. I put some of the GunSlick grease on the slide before heading to the range.. A BIG improvement, but still not acceptable. It's going to need a bit of work I think to make it reliable, nothing major, just some clean up on the feed ramp. I may hold off until the gun is broke in before I do anything with it.

As for the GunSlick grease I used, the slide after 75 rounds is still silky smooth. It actually reminds me of Mobile 1 Synthetic grease, I honestly cant see or feel a difference ( which doesn't mean a whole lot, but it's all I can go by ). I use Synthetic grease on my personal vehicles, so I may just use that once I use up all the GunSlick grease. The grease is still where it needs to be, although some did "leach" out, the little that did trapped the burnt powder and other junk, which basicly created a seal so none of it could get in the slide rails. The grease on the slide is still red, and not black, so I consider the little bit that leached out a good thing. I'm pretty happy with it. In fact with the gun still being so smooth, there is really no need to clean it, but I will anyways. So I will probably stick with it on the slide, but I will try some of the products listed here for other parts of the gun, and for my rifles as well..